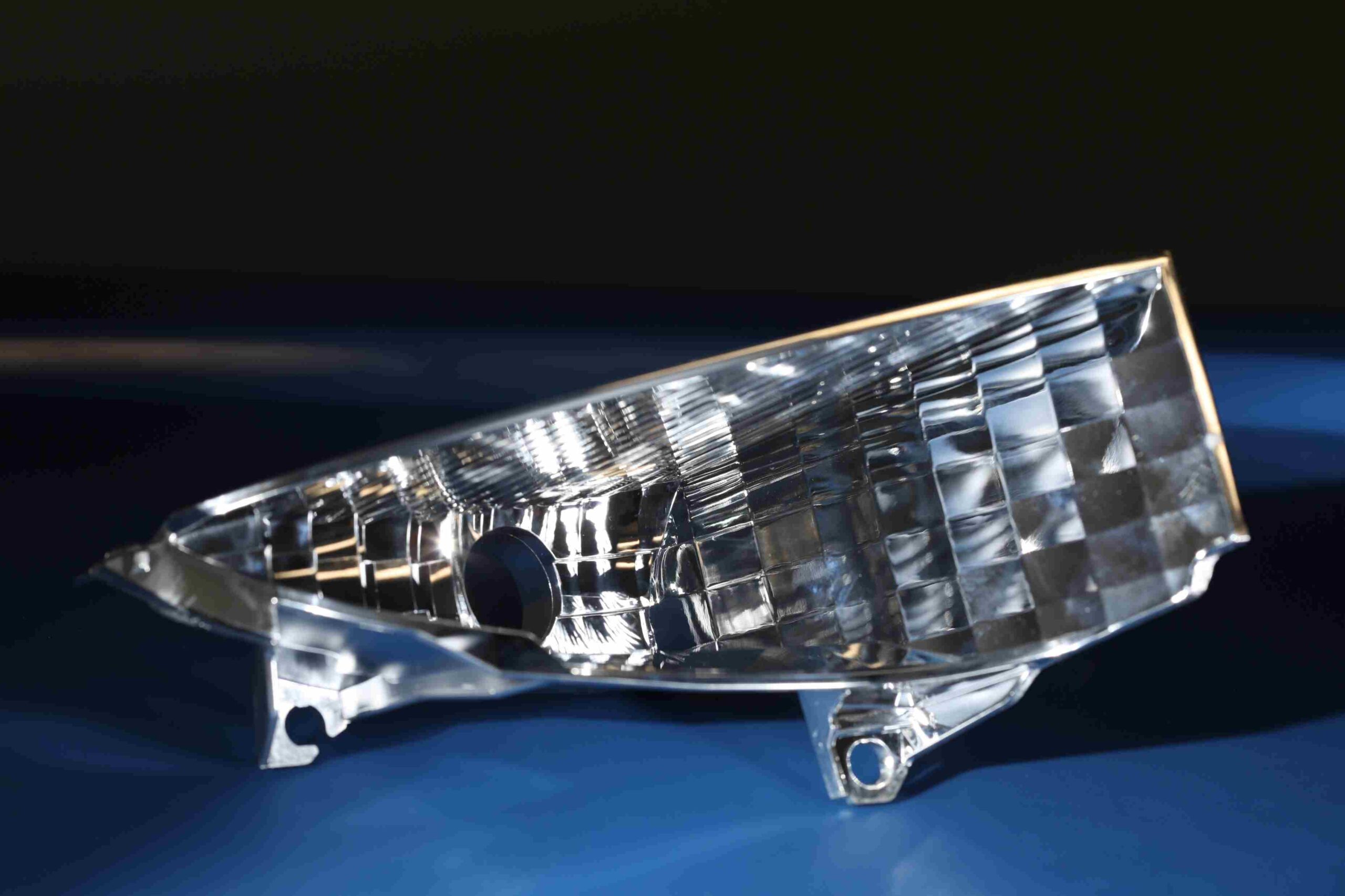

Exterior & Interior Lighting Molds.

High Quality & Performance Tooling.

As a premier, cost competitive manufacturer of quality products we have the ability to support the automotive lighting industry. Our long standing experience in this segment allows us to understand and adapt to your unique needs and expectations.

- Housings (CHL/RCL/BUL)

- Extensions / Bezels (CHL/RCL/BUL)

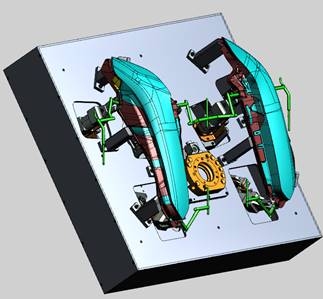

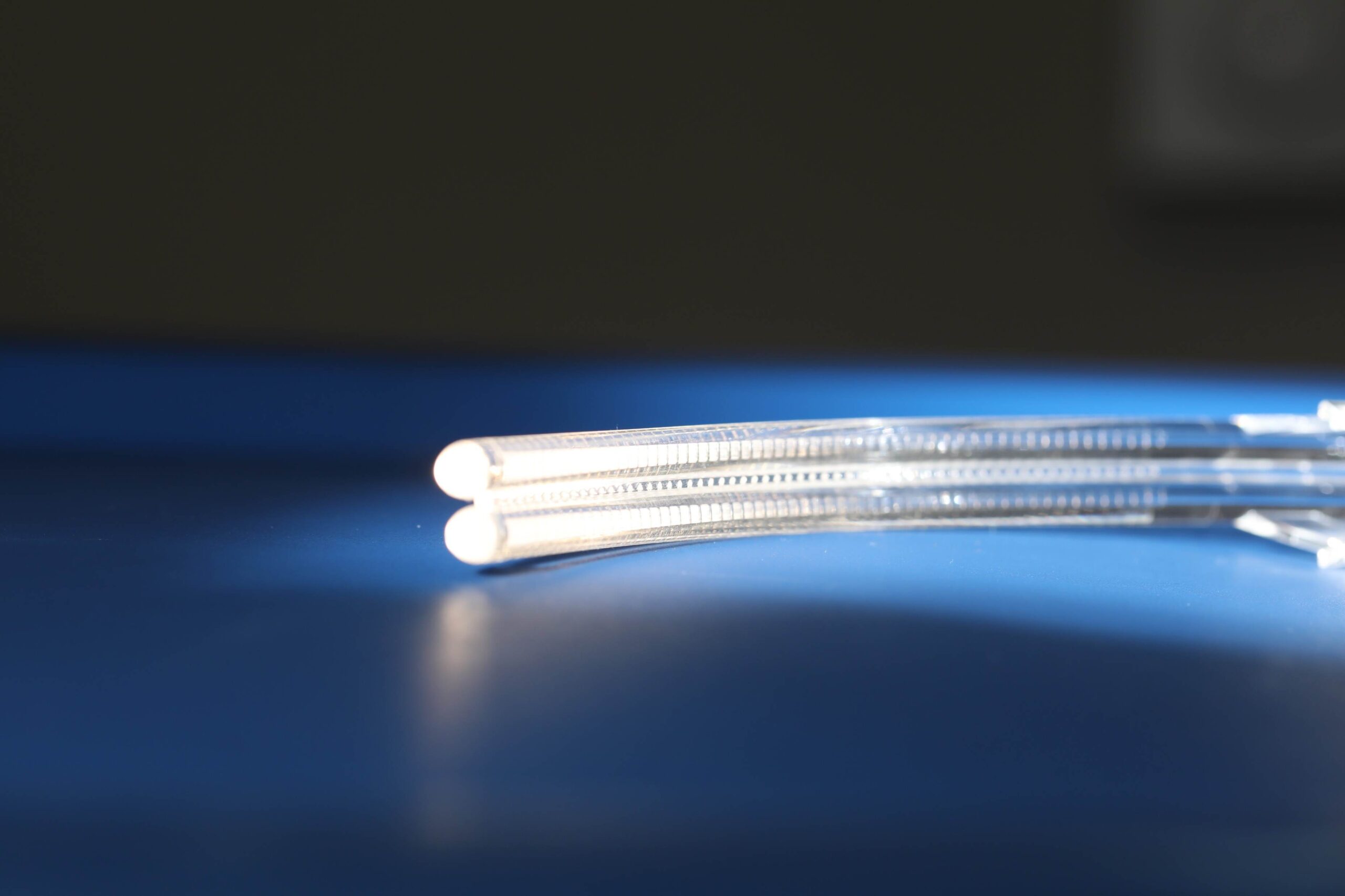

- Lens Tools – Inner/Outer

- Bezels (A, B, C, D, E)

- Reflectors

- Thermoset Tooling (Reflectors & Brackets)

- Brackets

- Bases

- 2-Shot Molds (Rotational/Lost Action/Pick & Place)

- 3rd Generation Owned and Operated

- 280 Employees

- 160,000 Sq. ft. campus

- ISO 9001/2008, ISO17025 Certified

- 150+ Lighting Projects

- Lower Costs

- Having advanced input into all aspects of the product development allows us to lower costs through less complex tooling and design time.

- Lower Lead Times

- Streamlining of the product design, simulation, and tool design into one contact can improve program timing weeks, if not months.

- Less Risk

- When you can consolidate your high-risk components/parts into one source, it will give you piece of mind. CTG can offer entire plastic solutions from concept to PPAP.

- More robust tooling conditions flagged at the design phase can significantly cut down on tool maintenance and molding costs throughout the life of the program.

- IS0 9001:2015

- ISO/IEC 17025:2005

- WBENC Certified

- IATF 16949 Under Development (Anticipated Approval in 2021)

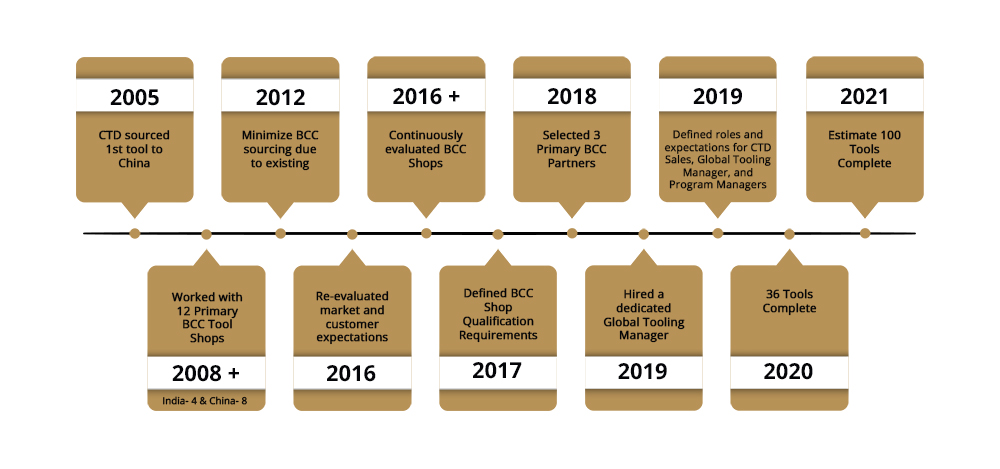

- Long Term Qualified BCC Suppliers

- Quote 3 Shops per project

- CTD Design & Build Standards

- Global Tooling Manager on Staff

- Qualifies Tools are built to CTD Standards

- PFS Status Report Tracking

- Bridge Run & Bridge Tooling

- Landing Services

- Economical Air Freight

- North American Lighting

- Magna Auto Systems

- Stanley

- JW Speaker

- Overall Value:

-

- One source for ALL your plastics product needs

- Meet our deadlines

- Professional work environment

- Reliable

- Proudly in business for over 65 years

- Specific Value:

-

- Customers work directly with an engineer

- Always improving CNC capabilities

- In-House Mold Sampling

- Innovative Micro Surface cutting

- Highly trained individuals

Automotive Lighting Injection Molding Projects

We Build Automotive Lighting Molds Exceptionally Well.

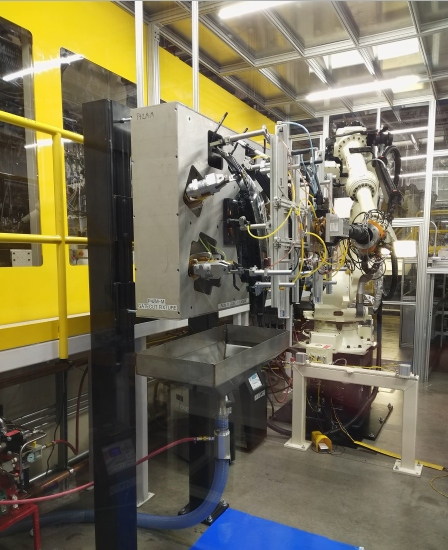

Today, CTG is a combined 160,000+ square foot manufacturing company that believes in continuous investment not only our employees, but also the latest CNC and Design Technologies. Our automotive lighting customers can be certain their tooling will receive the highest level of quality service available. With our ongoing commitment to investment and growth, Commercial continues to balance the resources of advanced technology and it’s people to deliver quality tooling in record time.

CTG Automotive Lighting Plastic Injection Molding Experience Works for You.

From concept to PPAP, our three divisions provide all the single source capabilities for your plastic parts needs.

- Plastic Injection Molds

- Compression Molds

- Prototype Molds

- Part Feasibility

- Mold Design

- Product Design

- Project Management

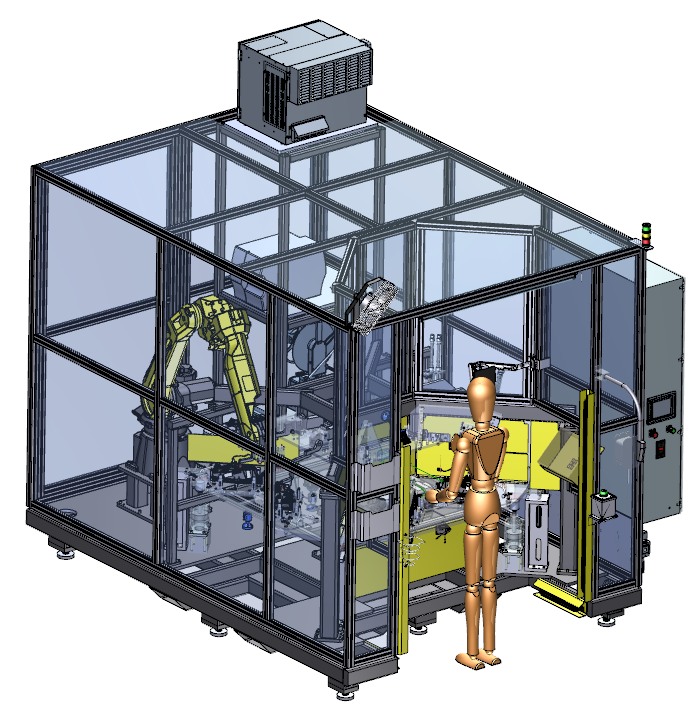

- Robotic Automated Assembly

- Compression Molds

- Check Fixtures

- Hot Knife Trimming

- IR Welding & Lamination

- Staking

- Applique Trim

- Screw Drive Assembly

- Thermo/Vacuum Form Tools

- Custom Presses

- Error Proofing Machines

- Sonic Trimming

- Trim dies

- Water Jet Nests

- WBENC Certified since 2010

- Press sizes ranging from 85 tons – 2,500 tons

- 2-Shot Capability

- Injection Mold Tryout

- Low & high-volume part production molding

- RJG trained & certified

- Emergency production support

- Product Transition Overlaps (Bridge Runs)

- Mold repair and maintenance

- In-house metrology support

- Warehouse capacity for raw/finished goods storage

Schedule a Visit to Learn More.

Contact us today to talk with a CTG Representative to setup up a facilities tour and discuss your automotive lighting plastic injection molding needs.