Let 185+ Years of Combined Experience Work for You

CG Automation & Fixture (CGAF) adds value for our customers by providing a full service approach to meet their needs. CGAF has a workforce of highly skilled employees, including proficient toolmakers, machinists, lab technicians, management, engineering, and sales staff.

CGAF has over 185 years of combined experience in the design and manufacture of down-line equipment, fixtures, gauges, applique form tools, trim dies, and trim presses.

Our team can coordinate every step of the project from initial feasibility review, project management, design, build, runoff, setup, installation, and training. CGAF also ensures your parts are to specification through our ISO 17025 and ISO 9001 accredited CMM lab.

CGAF utilizes NX 3-D design software, the most advanced CNC and CMM machinery along with the most advanced control technology to meet or exceed your requirements. Effective utilization of technology combined with a team approach is what sets us apart from the competition.

Our designers and engineers analyze every step of the project to ensure we design the exact component, per your specifications, and offer our best proactive solutions where needed. Once you have received your equipment, you will be able to analyze every part quality and perform value-added operations concurrently, which results in a qualified process and cost effective solution.

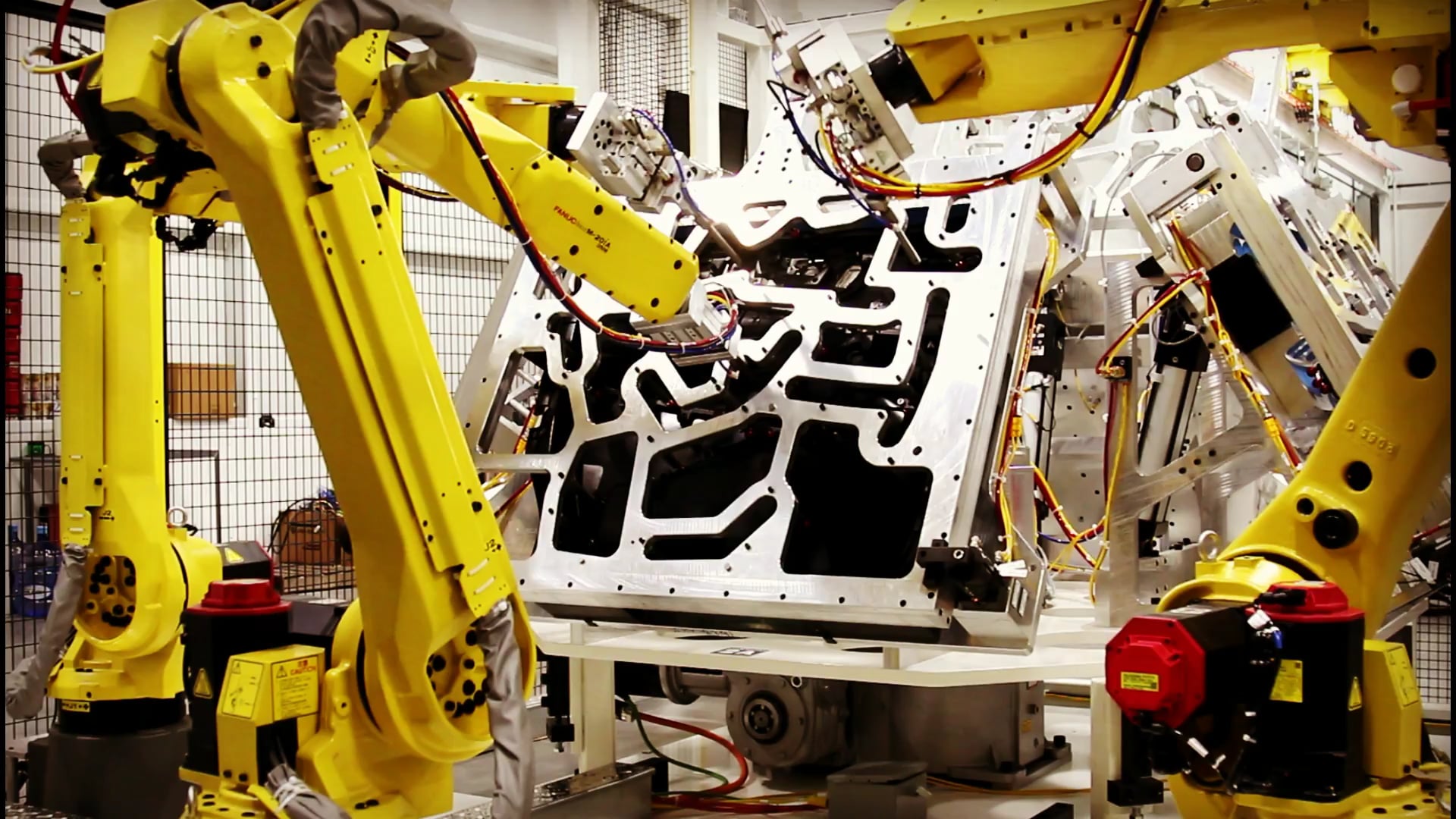

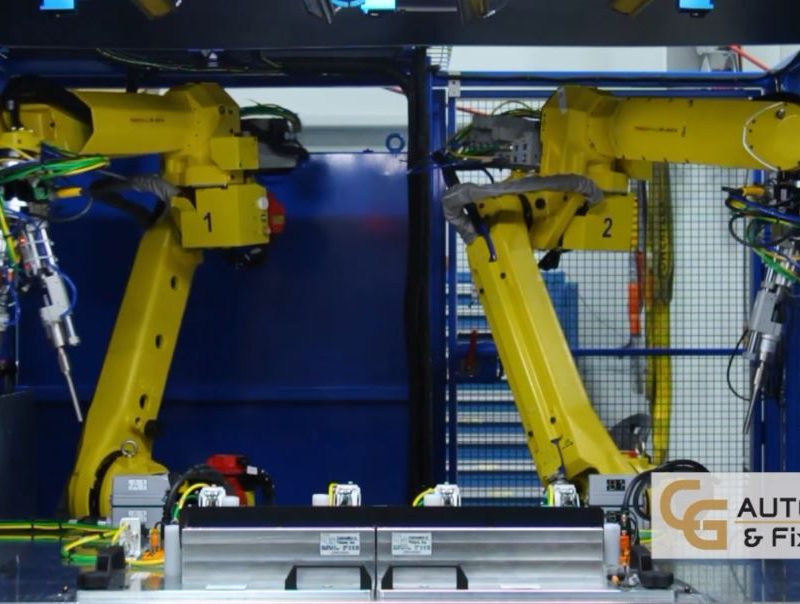

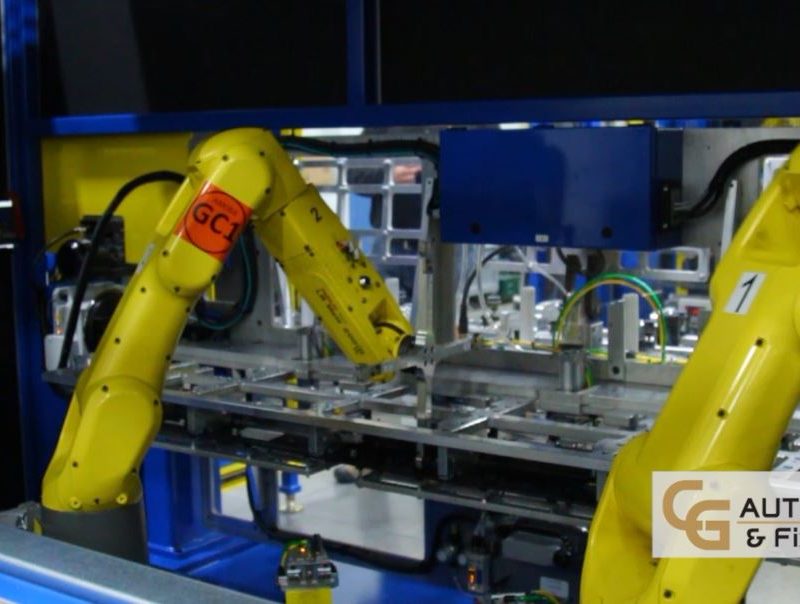

- Robotic Applications

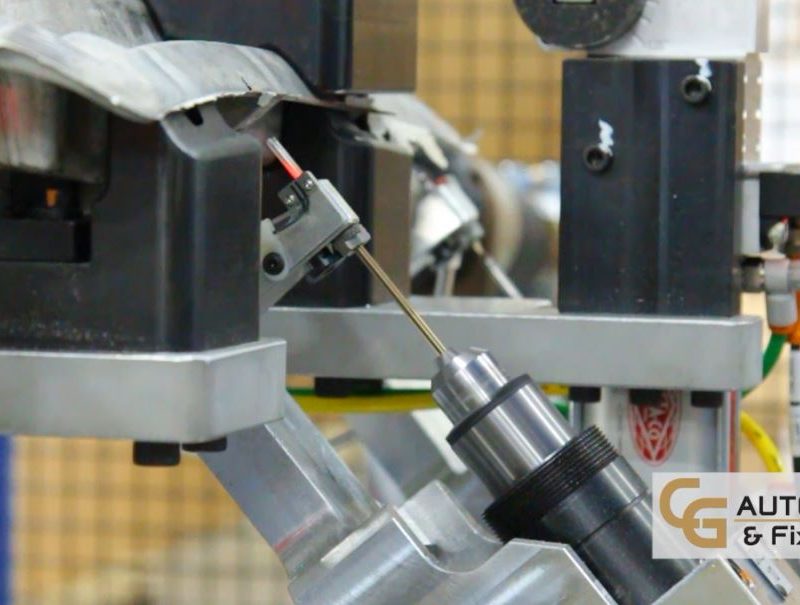

- Screw Install

- Clip Install

- Sonic Staking

- Sonic Knife

- IR Welding

- Ultrasonic Welding

- Hot-Air/Cold-Stake Welding

- Leak Test Machines

- Lamination Equipment/Tooling

- Custom Assembly Equipment

- Fold-back Machines

- Custom Punch Machines

- Press Lamination Tooling

- Thermoform/IMD Tooling

- Vacuum Activation Tooling

- Match Metal Trim tooling

- Fabric Alignment

- Seam Alignment

- Engineering Changes

- Repair

- Fold-back Machines

- Custom Punch Machines

- Attribute

- CMM Holding

- Variable

- Environmental Fixtures

- Laser Nests

- Water Jet Nests

- Leak Test Machines

Commercial Tool Group’s CG Automation & Fixture division offers a complete line of CMM first article contract inspection services, including inspection and certification of production tooling, gaging and fixtures.

- Parts Layout

- Capability Studies

- Third Party Certifications

- Gage R & R

- ISO-17025 Accredited

- Large CMM (Up to 75″W x 54″H x 125″L)

Our New Facility

Look inside our newly completed facility addition.

Check out Some of Our Work

Full Service Cost Effective Approach.

Turnkey Automation Solutions.

Along with CTD and CGP, CG Automation utilizes the same program management technology. Each company uses NX software and the EPICOR ERP system. By utilizing standard and scheduling systems, CGAF is able to effectively communicate design revisions, manage bottlenecks, and leverage capacity between facilities.

Our advanced engineering team is available for all customers and is a key resource for getting your analysis done in a timely manner. Over 100 combined years of multidisciplinary knowledge and a lean approach provides a competitive advantage for our customers. Our strategy is to be an extension of our customers’ engineering teams, and a valuable resource you can depend on.

- Pre-award lean workshops, allowing our customers to streamline their processes, reducing costs of labor, machines, and materials

- Pre-award budget assistance

- Best practice solutions for assembly/measurement options

- Part feasibility reports

- GD&T assistance

With the use of our state of the art design software and CNC equipment, CGAF is able to provide cost-competitive solutions with industry-leading quality. With the implementation of our FCS work holding system and design software, CGAF offers extensive design and machining capacity. Advantages to this include repeatability, accuracy, and a reduction in set-up time. This allows us to supply equipment manufactured to the highest standard with the lowest amount of now-value-added expenses.